Downtime in Manufacturing: What’s the True Cost?

Share

Downtime in manufacturing can wreak havoc on production standards. In fact, it is estimated that almost every factory loses at least 5% of productivity, with experiences as much as a 20% loss, due to downtime. A manufacturer’s bottom line can include up to 800 hours of downtime which translates into millions of dollars in revenue loss. Minimizing downtime in manufacturing is just as pivotal as maximizing quality and output to maintain contribution margins. To understand the true cost of downtime, you must track and categorize every aspect of as well as analyzing the cost factors associated with each stop in production.

What is Downtime in Manufacturing?

Downtime in manufacturing is defined as any period of time when a machine is not in production. The total amount of downtime a factory experiences includes any stops during production that cause a loss of revenue for the company.

Downtime in production is separated into two different categories: planned and unplanned. Planned downtimes are scheduled and budgeted stops during production such as scheduled maintenance and product changeover. Unplanned downtime in manufacturing occurs when equipment that is scheduled to be in operation has an unexpected event such

as equipment failures or running out of material occurs. Though all downtime has a price, it is pivotal for manufacturers to service their machines as a form of prevention to decrease the chances of unplanned downtime, a much costlier process.

Planned Downtime In Manufacturing

Scheduled machine maintenance is an example of planned downtime in manufacturing. Daily maintenance programs can include cleaning, lubricating parts, making minor adjustments and detecting minor problems that can be corrected before they become a major problem that can shut down a production line. Product changeover is another example of planned downtime. Product changeover is a process that occurs when a manufacturing plant switches from producing one product to another during a planned downtime. A typical changeover consists of setup and adjustments such as ramping up and down both at the beginning and end of a run.

Planned downtime still has a cost to revenue, so the priority is to expedite machine maintenance and product changeover to remain within the budgeted timeframe. This isn’t always the case and delays have an impact on the Overall Equipment Effectiveness (OEE) as well as contribution margins.

Unplanned Downtime In Manufacturing?

Unplanned downtime are any unexpected stops that occur during production. The stops occur without notice and can last any length of time and can create massive backups along the production line.

These unplanned halts during production eat into the maximized hours in a work day and inevitably diminish optimized revenue.

Many times, this can be due to hardware or process failures; for example, a pump, motor or fan could fail on a piece of equipment which would require unplanned machine maintenance. The time needed to amend the failure is in direct correlation to the constraints of having the necessary materials to fix the hardware, as well as having a knowledgeable workforce with the ability to address and resolve the issue. The consequences of these unplanned stops are a loss in hourly production rates and are translated into a loss of revenue. For every moment a machine is not operating, revenue is lost.

Machine Jams: An operator must be present to physically manipulate the component that is jammed on the machine. If an operator is not present on the factory floor, one must be brought in, and downtime is exacerbated by this wait.

Part Failures: Machine downtime can be caused by part failures such as pumps, belts, sensors and motors that require replacement or repair. The length of downtime is determined by the availability of the materials necessary to make the required repairs, and if a maintenance technician is available to make those repairs.

Water & Oil Leaks: The size of a water or oil leak and the accessibility to the leak by an operator will affect the length of downtime. Containment of a leak to prevent damage to other machine components is also a constraint on how quickly an operator can have the production line running efficiently again.

Inadequate Maintenance: Unplanned downtime can result when machines are not maintained or checked adequately during scheduled inspections. With inadequate maintenance, the probability of damage and prolonged downtime not only increases but creates an environment that is not safe for factory floor workers.

What Are The True Costs of Downtimes?

The True Costs of Downtime (also known as TDC), consists of analyzing all cost factors associated with downtime. The two variables of TDC are tangible costs and intangible costs. This information is then used for management decisions and for the justification of costs.

According to the Vanson Bourne Research Study, roughly 82 percent of companies that have experienced unplanned downtime over the past three years, have experienced outages that lasted an average of four hours. The cost of downtime came with a price tag of an estimated two million dollars. With knowledge of these statistics, the priority for manufacturing companies is to achieve maximum efficiency by eliminating unplanned downtimes altogether.

Tangible costs are the physical consequences of downtime in manufacturing and are recorded and tracked by data.

Lost Production: Every product that a manufacturer produces represents some amount of potential profit. Whether it’s pennies or dollars, these values add up over time-based on how fast each unit is produced. For example, let’s say a company can produce 100 units per minute, and each of these units represents a potential of $1 of profit. For this company, the cost of downtime in manufacturing based on lost production would be $100 per minute, $6000 per hour, etc.

Lost Capacity: When all systems are fully operational, a manufacturing plant that is running at suboptimal capacity. It is important for a factory to plan for when there is a sudden increase in demand. When this occurs, the factory will need to operate at a higher capacity to fulfill the added business. Reducing production downtime is important because it creates additional capacity for free and makes situations like these a non-issue.

Direct Labor: When you reduce downtime in manufacturing, your production levels go up while your labor stays the same. This will decrease the labor cost per unit. Also, when there are less issues, employees can focus on their main task and increase their efficiency.

Inventory: The cost of holding inventory is typically around 10%-30% of the inventory’s value, per year. This means that if you have 1 million dollars of inventory, it would cost $100,000 to hold it for a year. One cause of downtime is changeover between products. Reduced changeover downtime will allow smaller lot sizes and lower inventory levels, which will lead to a lower cost of holding.

Intangible Costs Are Less Obvious, Focus On Factory Personnel

The intangible cost of downtime in manufacturing is less obvious because it is less concrete. Many of these costs are focused on the relationship of a workforce within a certain environment and how humans and machines interoperate.

Responsiveness: When downtime occurs, employees must focus on addressing these issues as their top priority. Since the cost of downtime in manufacturing is so significant, it becomes more important to solve these problems than focusing on customer service issues. For example, the TDC in the automotive industry is around $22,000 per minute!

Stress: Downtime can cause a lot of stress in both employees and the machines that they are operating. When a system isn’t working, it can get overwhelming for an employee to accomplish their daily tasks. On the other hand, if a machine needs to produce at their maximum capacity for long periods of time, it becomes more likely that they will malfunction. People and machines perform better under less stress.

Innovation: Downtime can be a very time-consuming issue for a business. This takes away time from other things like innovation and creative brainstorming opportunities. It is much more important to make sure a current system is working before imagining how to improve that system’s capabilities for the future.

Calculating The True Cost of Downtime

The true cost of downtime in manufacturing is determined by the impact an outage will have on employees and productivity. By identifying the cost of employee downtime as well as the cost of loss of orders, manufacturers can calculate a concrete number the true cost of unplanned downtime.

To determine the cost of employee downtime, first calculate the average hourly pay rate of impacted employees. Second, assign a percentage for the level of impact that unplanned downtime will have on productivity. For example, if only 30% of the product line is operational, the loss in productivity equals 70%. If you have 150 employees at an hourly rate of $50 and they experienced a 70% productivity rate loss, the total cost of employee downtime would be $5,250.

The cost of impacted employees from unplanned downtime directly correlates to a decline in product being manufactured, leading to a loss in orders. The overall cost is also compounded by the inability to produce. To calculate this loss, calculate the production hours per day, the average amount of units produced and the hours of unplanned downtime. Dividing the average units produced by the hours of unhalted production during a day. For example, $300,000 in sales orders over the course of an eight-hour shift amounts to $37,500 in sales orders created per hour. Multiply this revenue by the total hours of unplanned downtime will reveal that $150,000 is the total cost of unplanned downtime.

Why Is Knowing The Cost Of Downtime Important?

There are many reasons why understanding downtime costs is important to optimizing day to day operations throughout production. For example, if you are aware that a six-hour outage for a major repair will cost $500,000, you will take preventative measures to avoid this outage as smaller scheduled repairs that consist of 20-30 minute stops and have a much smaller price tag.

By understanding the importance of downtime costs manufacturers can make data-driven decisions with confidence. Operations teams can avoid unnecessary costs and extensive planning and preventative actions can be taken to avoid significant amounts of unplanned downtime.

How To Reduce Downtime In Manufacturing

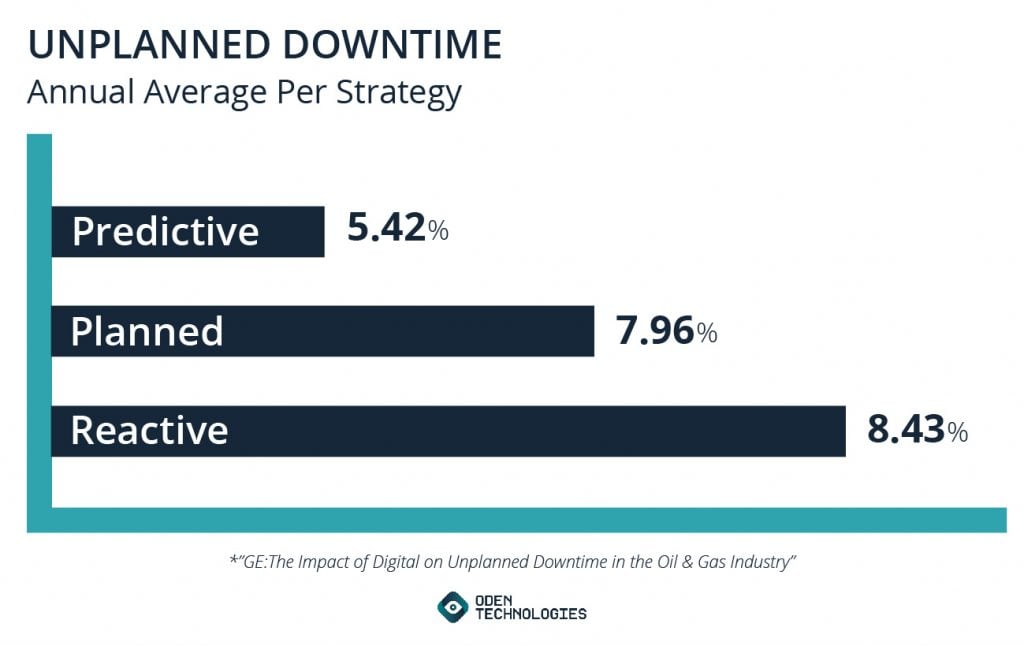

A GE Study on the oil and gas industry found that only 24% of global operators who participated described their maintenance strategy as “predictive,” or an approach that is based on the efficient and effective collection and management of data and analytics. The most prevalent strategies used by the participants in the study were the reactive approach or the planned approach.

In terms of the unplanned downtime associated with each of the three approaches:

• Reactive strategies averaged 8.43% in unplanned downtime annually.

• Planned strategies averaged 7.96% in unplanned downtime annually.

• Predictive strategies averaged 5.42% in unplanned downtime annually.

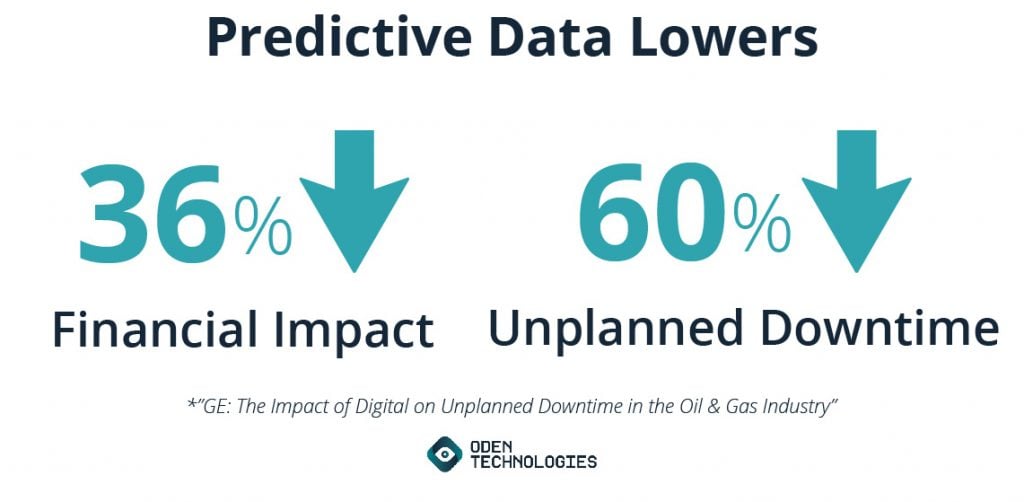

Compounded by the additional costs of repair, labor, transportation and equipment, the reactive and planned approaches lead to a hemorrhaging of revenue at just shy of 60 million dollars annually. A predictive, data monitoring approach cuts those losses by nearly 40%. The numbers lend truth to the power of predictive data and analytics to significantly minimize the amount of downtime a manufacturing plant may see.

Challenges Of Predictive Maintenance In Manufacturing

It is important to note that true “predictive maintenance” has its inherent challenges when implementing. A significant investment of time is necessary to gather the data needed to predict very specific scenarios including downtime in the manufacturing process.

A good rule of thumb for predictive analytics is that you need 10 times the data of the scenario you are looking to predict. If you are looking to determine when a critical piece of machinery needs to be replaced, like a motor, that motor would need to fail ten times in order to gather enough data to create a reliable prediction.

The solution to expediting the implementation of a predictive strategy and moving away from costly planned or reactive approaches is by combining the power of condition-based monitoring of the factory floor, machine learning and predictive analytics.

Leveraging Machine Learning And Predictive Analytics

Condition-based monitoring is when machine learning models look for a specific set of conditions that indicate a machine failure may occur. The temperature and vibrations of key components on a machine are set based on optimal controls. These controls are continuously monitored, and when measurements on a machine are experiencing any deviations, such as a prolonged dip in temperature, or an increase in vibration, alerts are sent to notify factory personnel of a possible failure.

Predictive analytics are a tool that can be used to alert teams when high-productivity components, such as pumps, fans and motors, signify they might fail. Alerts are customizable to factory floor conditions or any combination of metrics you may choose. If the condition-based monitoring registers a machine’s pressure has dropped five times over the course of ten minutes an alert is triggered to notify factory personnel that action is necessary. This alert not only pinpoints the deviation in optimal controls but empowers the factory floor operators to act decisively to prevent unplanned downtime.

The Perfect Downtime Monitoring Platform

The perfect downtime monitoring platform combines real-time monitoring and pareto analysis with machine learning and predictive analytics. Real-time monitoring allows manufacturing companies to access production data while it is happening. It allows you to see where a kink in the production line may be occurring, why it happened, when it happened and much more. Pareto analysis is a technique used to assess and prioritize problems during production. By analyzing these, managers are able to focus their efforts on each individual problem according to the strength of its impact on daily operations.

Categorizing your reasons for production downtime into a Pareto Chart allows you to see the largest causes of downtime in real-time. With visual representation of downtime, operators can determine what percentage and factors are causing downtime and will be able to prioritize what to fix based on frequency and difficulty of the issues to solve. Machine learning & predictive analytics allow you to predict and prevent issues by alerting operators or engineers so they can take corrective action immediately, ultimately costing them 15 minutes versus 5 hours of unplanned downtime in the future.

Downtime Calculation Applications In Many Industries

Downtime calculation applications are useful in many manufacturing industries today. Oden Technologies helps a variety of industries limit unplanned downtime through the use of machine learning and predictive analytics including food and beverage, wire and cable, and automotive.

Across the board, unplanned downtime is costly. Failure of machine components or deviations from optimal settings not only lends to the production of scrap, but can also create unsafe working conditions for factory floor personnel. The improper manufacture of resources, whether it is oil, or wire and cable will have a massive impact on the bottom line.

Oden’s approach to condition-based monitoring and predictive analytics will expedite the implementation of a predictive approach on your factory floor to drastically prevent unplanned downtime, saving a tremendous amount of money in lost revenue.

Get Oden’s Help

Downtime in manufacturing can be a major headache during daily operations and inevitably results in a loss in revenue. The less downtime, especially unplanned, the better.

Learn more about using machine learning to eliminate unplanned downtime in manufacturing as well as predict and prevent production failures.

The post Downtime in Manufacturing: What’s the True Cost? appeared first on Oden Technologies.